In 2020, the total value of projects planned or underway in the Middle East and North Africa region was USD 4324.43b, according to numbers put out by Statista. Indeed, the construction sector has been one of the most prominent industries in the region, in many cases as important as the oil and natural gas industry. This means that the carbon emissions produced by this industry can also sky-rocket whenever the region witnesses a boom in construction-based activity and real estate.

Embodied carbon is the term associated with carbon emissions that are caused by buildings and construction activity. According to the World Green Building Council, buildings account for 39% of global energy-related carbon emissions today, with 28% coming from operational emissions, such as the energy required to heat, cool, and power them, and the remaining 11% stemming from materials and construction. This is one of the major industries that must be decarbonized if net-zero ambitions will be achieved.

Dr Steven Griffiths, Senior Vice President, Research and Development at the Khalifa University in Abu Dhabi, explained that the Middle East is a “major producer, consumer and exporter of many of these noted industrial products, particularly those that makeup about 80% of industrial emissions” which includes oil and gas, steel, cement, ammonia (chemicals) and aluminium.

With significant amounts of emissions relating to the construction industry, what is the Middle East doing to tackle it? The answer, as one might expect, is not straightforward. While the governments of these countries have announced ambitious goals to achieve net-zero emissions and launch massive sustainability programs, many construction companies are struggling to implement solutions that can reduce carbon emissions.

Aishwarya Chengappa, a sustainability consultant for Ramboll remarks that “other than the operational carbon emissions, it’s majorly the use of raw materials that have a high energy consuming production process and are usually transported through longer distances.”

This causes companies to drive up their carbon emissions, especially because sourcing local materials can often be more expensive compared to shipping them from overseas. Apart from this, reducing emissions also requires companies to adopt certain policies which they might not yet be willing to do.

Chengappa explains, “Sustainability strategies generally require commitments and policies to be made that clients hesitate to adopt. Awareness is another factor, not a lot of clients have the knowledge or information pertaining to Embodied Carbon and do not understand the need for addressing such issues.”

A concerned Chengappa also said that of all emissions, it is embodied carbon that is least talked about in the Middle East. Dr Griffiths said that the Middle East needs to be very concerned about decarbonizing these industries for mainly two reasons.

One is to meet “domestic net-zero ambitions. Glass, cement, steel and aluminium are key construction materials with high levels of embodied emissions. With regional construction activity so high, this is an important matter to address.”

Secondly, to maintain “competitiveness in exports. Many key regional exports have significant embodied carbon, including refined oil products, ammonia, steel and aluminium. With growing traction for Carbon Border Adjustments on imported products in locations such as the EU, reducing embodied emissions is essential.”

What can be done to reduce such carbon emissions? For one, Chengappa says that using locally sourced materials in construction can help companies cut back significantly on their carbon footprint. This helps them to avoid the emissions caused by all kinds of shipping.

Dr Griffiths also says that hydrogen can play in reducing embodied emissions in many industries, “most importantly ammonia (chemicals), refined oil products and iron and steel.”

Because many countries across the Middle East aim to play a key role in low and zero-carbon hydrogen production, their best near-term opportunities are in leveraging low and zero-carbon hydrogen in local industrial clusters. “Clusters can help in bringing the needed scale to hydrogen supply and demand that is necessary to achieve increasingly reduced costs.”

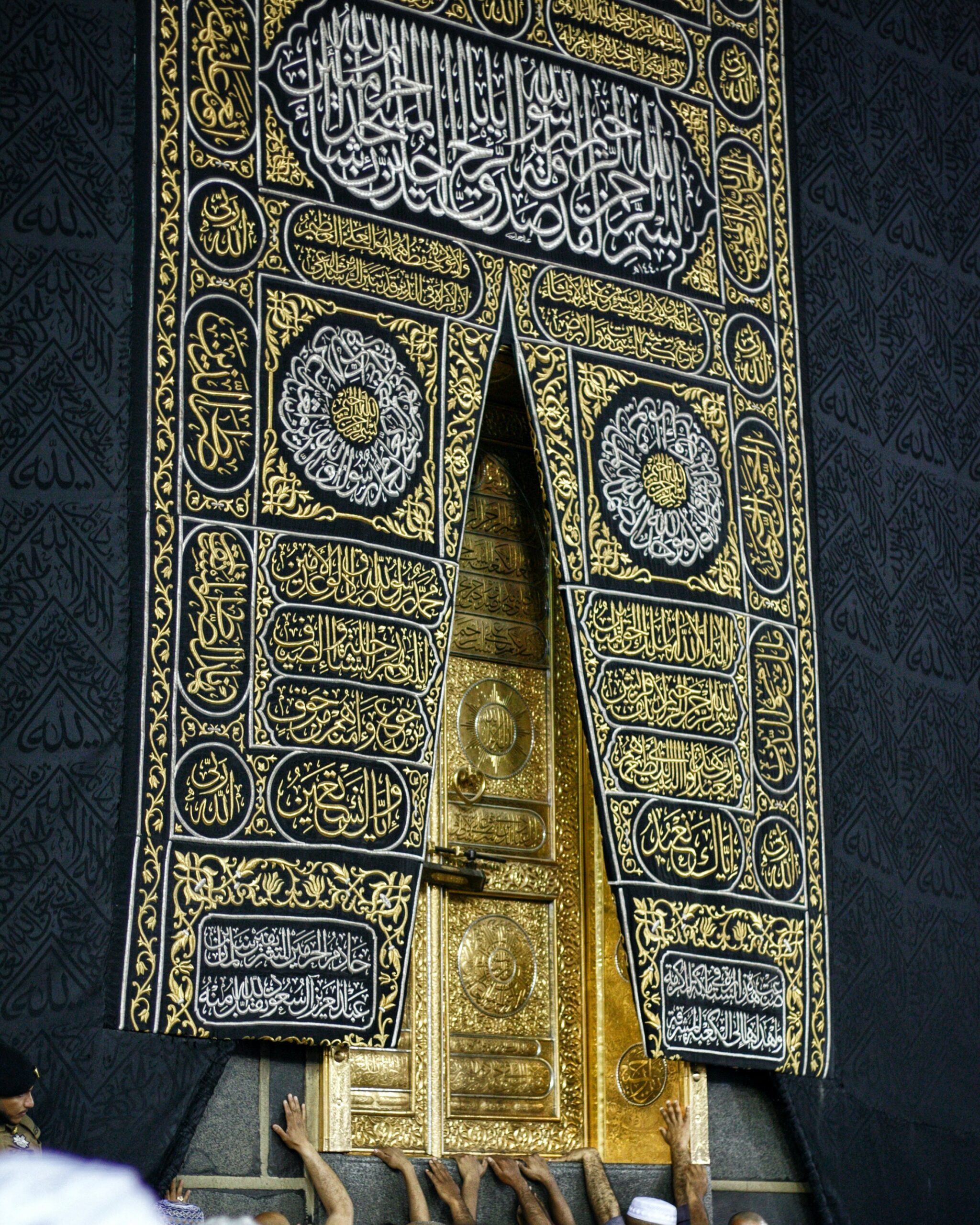

Image Credit: Duminda Perera on Unsplash